with technique instead of

conventional production.

This perspective makes us different.

HOW WE PRODUCE...

Pre Production

Before the production potential risks are evaluated by the technical team and solutions are offered to minimize the risks.

Digital efficiency and Quality Tracking system Digital Process, Inline and Endline quality control and data analysis. Upright Table for quality control of hanged products

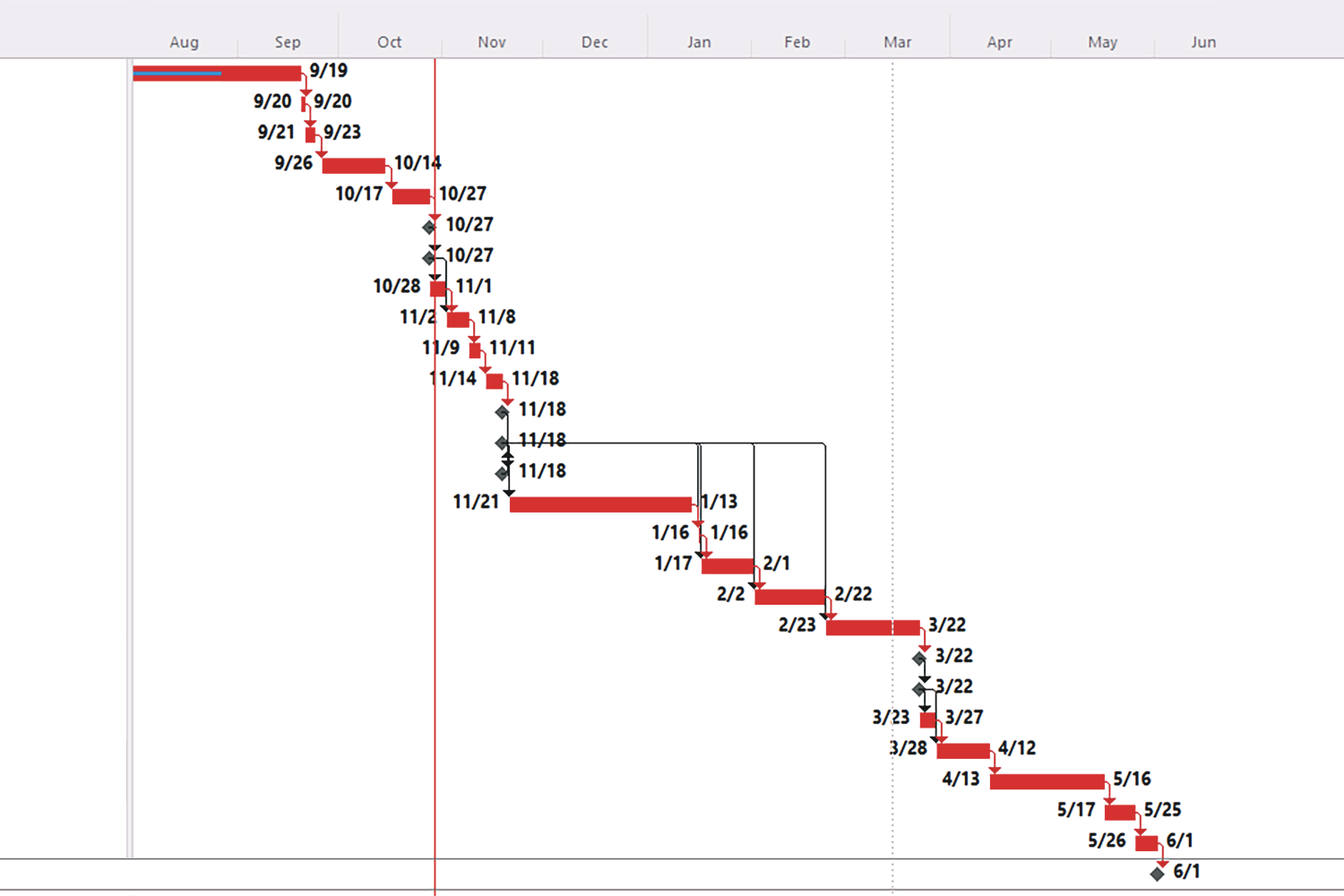

Critical Path

Each Order is planned with all its details and presented to the customer with this plan details.

Inhouse Lab

Technical evaluations and tests of each style in terms of fabric, material and design are made by our qualified laboratory technicians, and the results are evaluated with the technical team and shared with the customer via RA (Risk Assasment).

Engineering

MTM method time studies and production automation are supervised by our engineers. The efficiency of each style is calculated and checked by our engineers before the production start.

Inhouse Factory

We are flexible according to the order quantity at inhouse factory, the cutting, sewing and the finishing stages are programmed according to each quantity.

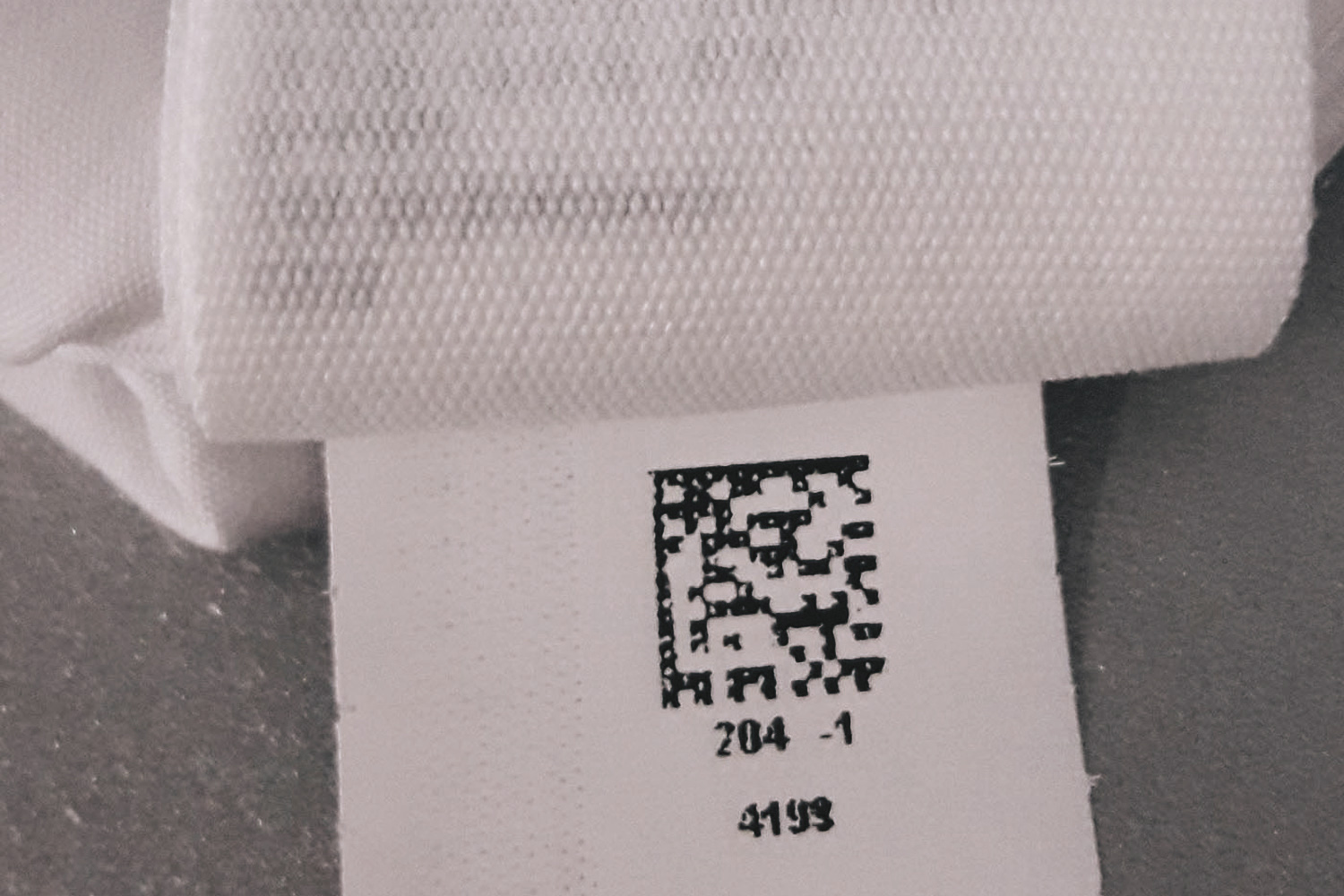

Traceability (RFID)

The products in the packeage checked by the RFID devices and the RFID tag shows us the quantities of the products in the box.

The tracking system technology, helps us to track every product and so, if there is an error in the product, we can detect all staff who sewn the product. With the tracking system, we increase the responsibility and therefore the quality of the work done.

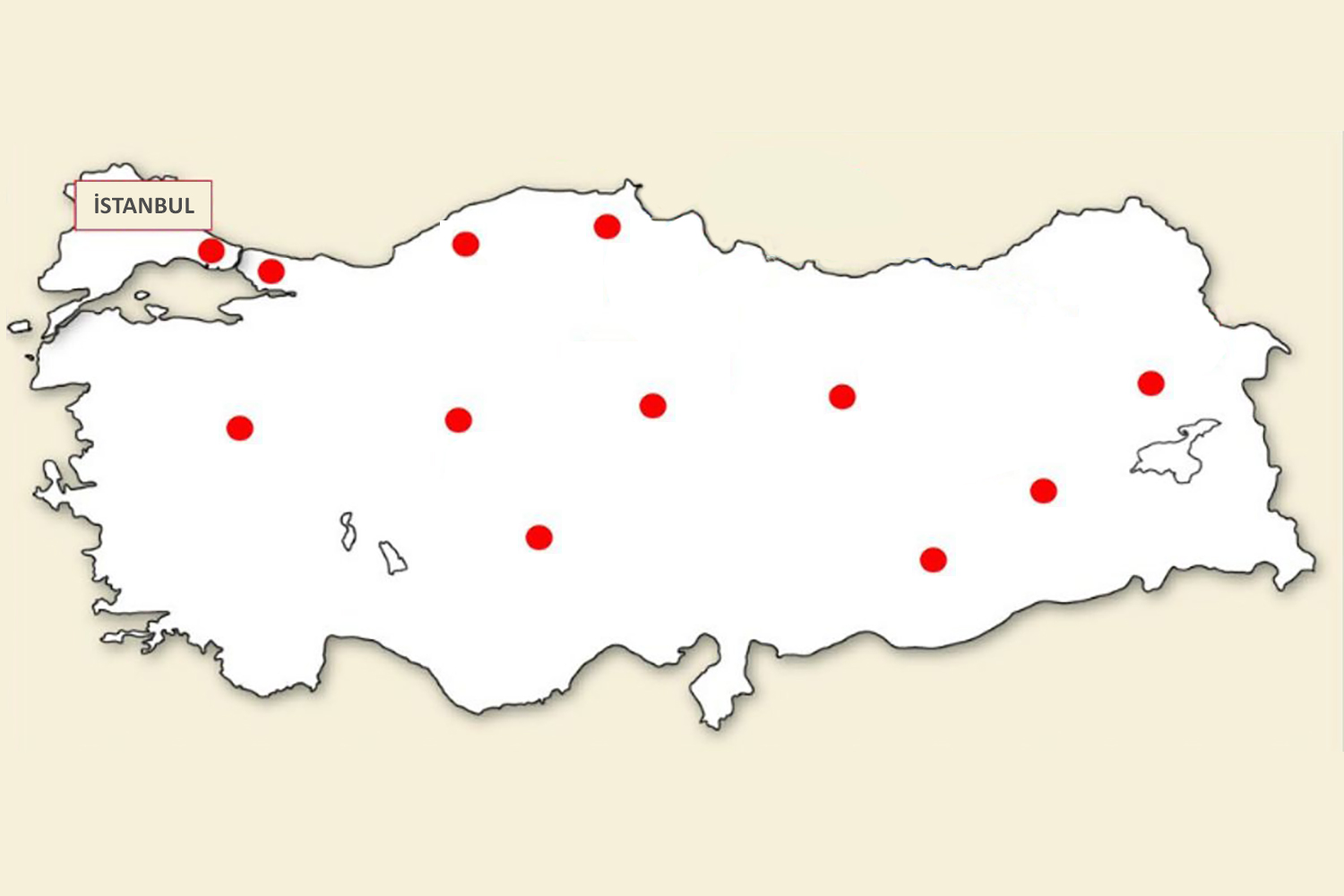

Subcontractor and Workmanship Programme

We update ourselves and our subcontractors day by day with continuously developing technology andquality-oriented trainings.